-

Review

-

Original Paper

28 February 2026

28 February 2026 -

Original Paper

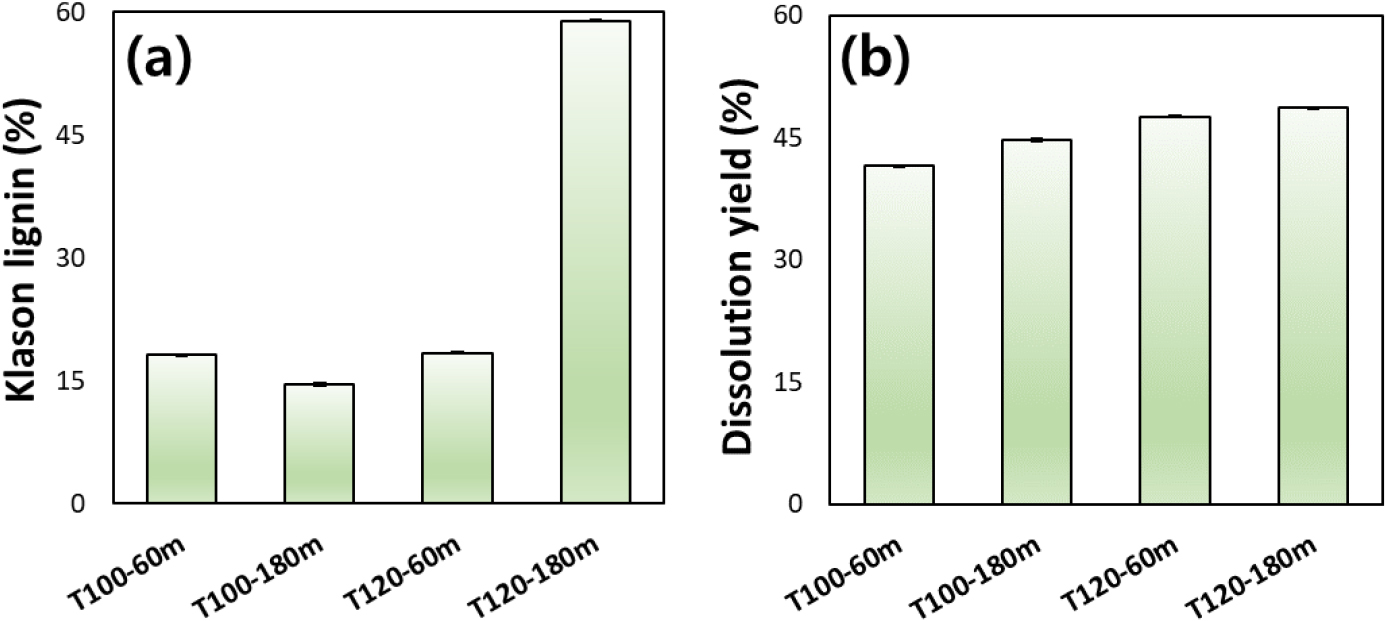

- Effect of Pulping Condition on Bamboo Pulp Properties in Glycol Ether-Based Organosolv Process

- Sa Rang Choi, Jiae Ryu, Jung Myoung Lee

-

Original Paper

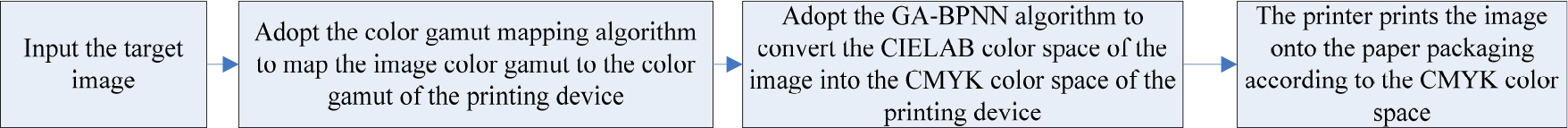

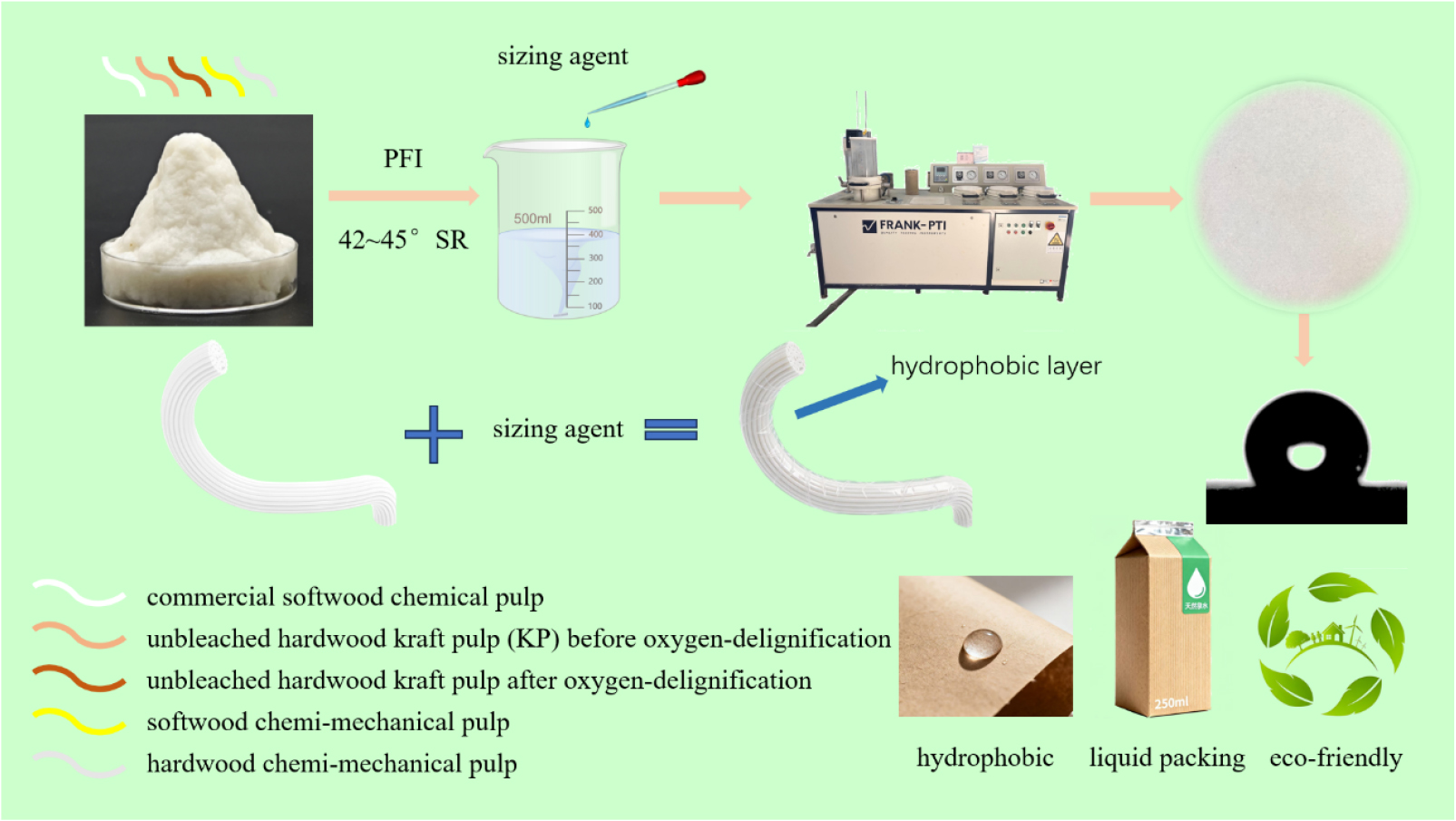

- Influence of Sizing Treatment on the Hydrophobicity and Strength Properties of Cellulose-Based Paper Materials for Liquid Packaging

- Hao Liu, Guihua Yang, Ming He, Shaoguang Wang, Qimeng Jiang, Chenyue Yu, Jiachuan Chen

-

Original Paper

-

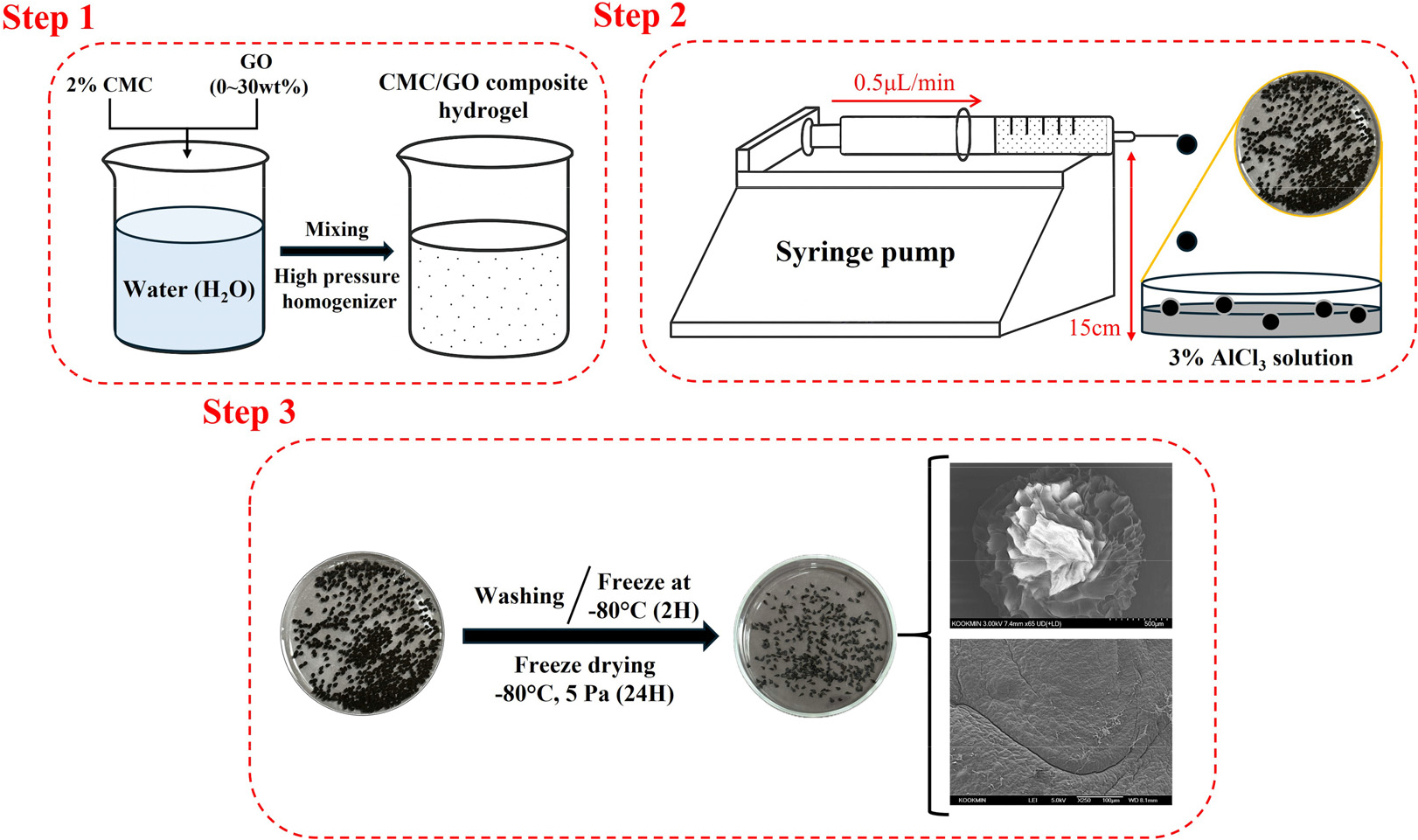

Fabrication of Carboxymethyl Cellulose/Graphene Oxide Composite Beads and Evaluation of Their Adsorption Behavior for Efficient Removal of Methylene Blue from Aqueous Solutions

수용액 내 메틸렌블루 제거를 위한 카르복시메틸셀룰로오스/그래핀옥사이드 복합 비즈 제조 및 흡착 거동 평가

-

Jae-Young Kim, Soon Wan Kweon, Dae-Hyun Jang, Hyoung Jin Kim, Jae Ho Ryu, Tai Ju Lee

김재영, 권순완, 장대현, 김형진, 류재호, 이태주

-

Fabrication of Carboxymethyl Cellulose/Graphene Oxide Composite Beads and Evaluation of Their Adsorption Behavior for Efficient Removal of Methylene Blue from Aqueous Solutions

-

Original Paper

-

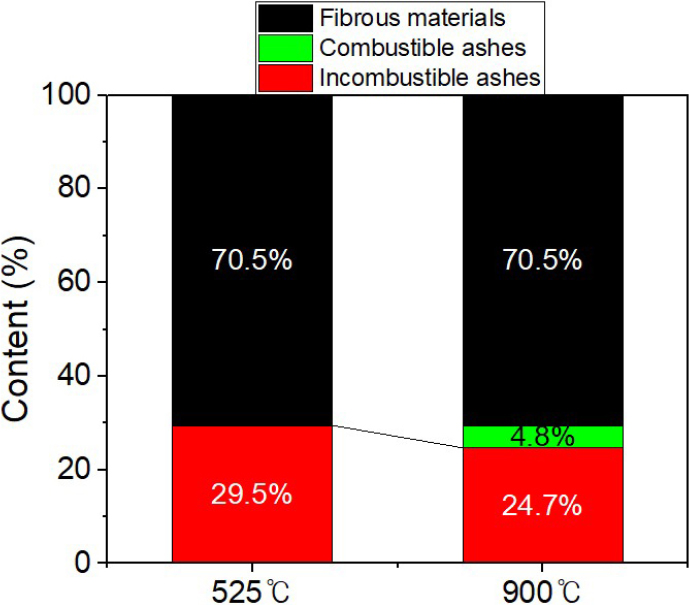

Nanofibrillation of White Water Solids and Their Application to Papermaking Process

백수 고형분의 나노피브릴화 및 이의 제지공정 적용

-

Seung-wook Park, Kunhee Lee, Hakmyoung Lee, Hye Jung Youn

박승욱, 이건희, 이학명, 윤혜정

-

Nanofibrillation of White Water Solids and Their Application to Papermaking Process

-

Original Paper

-

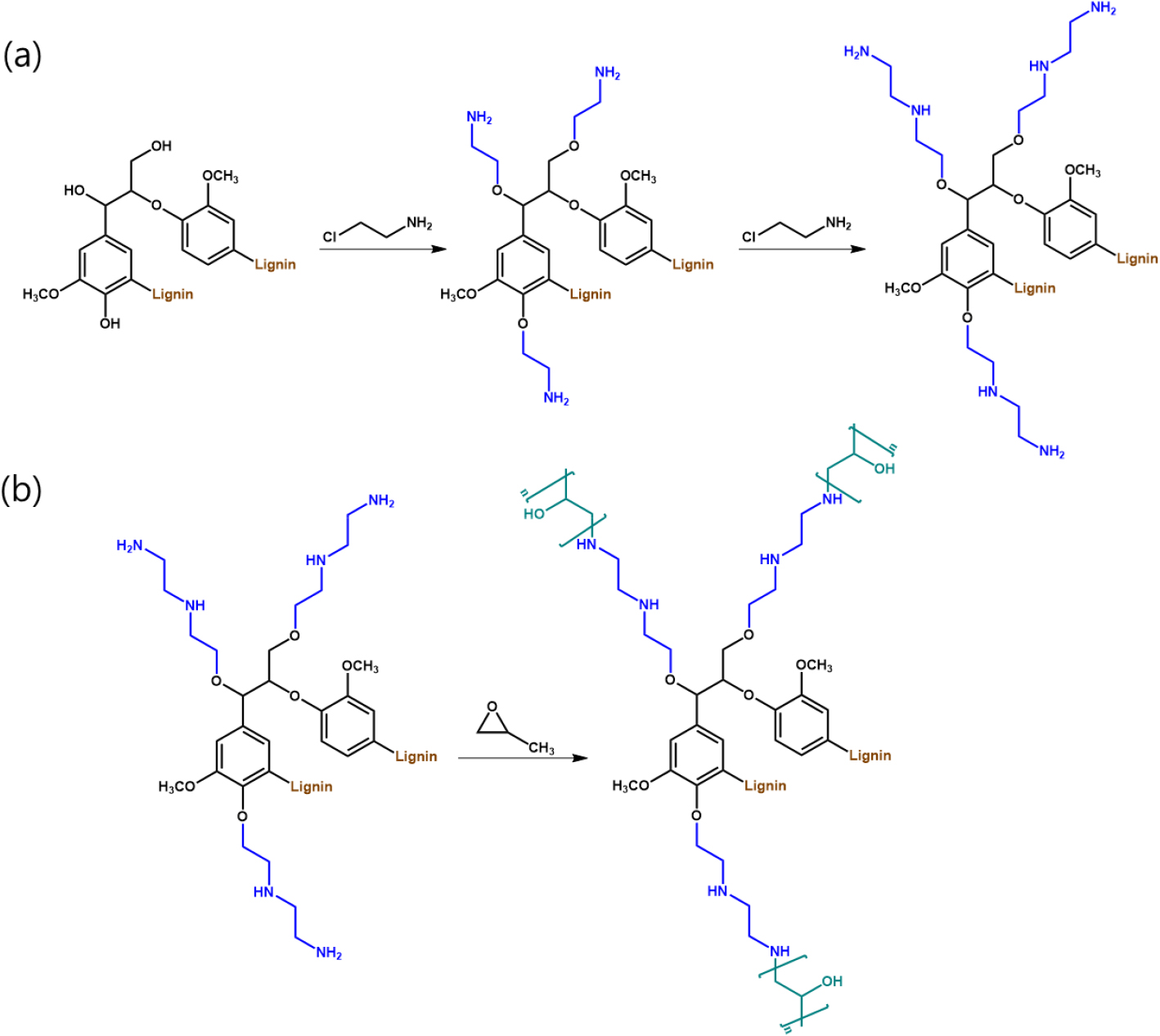

Dual-Functional Lignin via Amination and Oxypropylation for High-Strength Hydrogels with Enhanced Network Integrity

아민화 및 옥시프로필화를 통한 이중 기능화 리그닌 기반 고강도 하이드로겔의 네트워크 안정성 향상

-

Min Soo Kim, Ji Won Heo, Yong Sik Kim

김민수, 허지원, 김용식

-

Dual-Functional Lignin via Amination and Oxypropylation for High-Strength Hydrogels with Enhanced Network Integrity

-

Original Paper

-

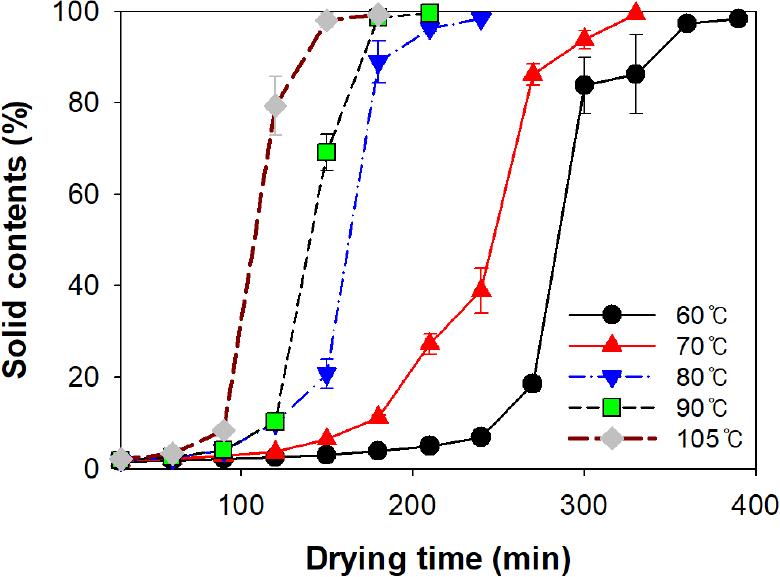

Effect of Drying Temperature on Network Structural and Absorption-Retention Properties of CMC/Starch-Based Superabsorbent Polymers

건조 온도가 CMC/전분-기반 고흡수성 소재의 네트워크 구조 및 흡수·보수 특성에 미치는 영향

-

Ha-Neul Kim, Byoung-Uk Ch

김하늘, 조병욱

-

Effect of Drying Temperature on Network Structural and Absorption-Retention Properties of CMC/Starch-Based Superabsorbent Polymers

-

Original Paper

-

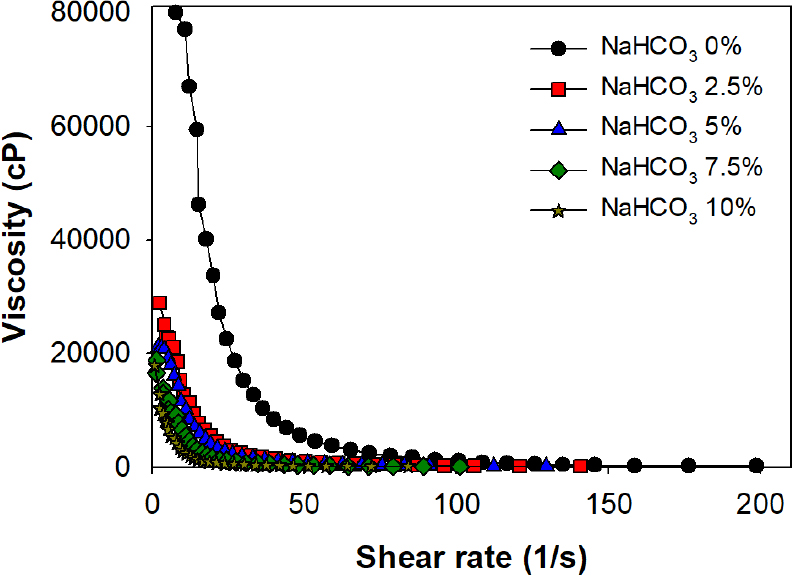

Enhancement of Saline Absorbency in CMC/Starch-Based Superabsorbent Polymers by Incorporation of Sodium Bicarbonate

중탄산나트륨 첨가에 따른 CMC/전분 기반 고흡수성 고분자의 염수 흡수 특성 향상

-

Chan Hee Shin, Young Lae Kim, Byoung-Uk Cho

신찬희, 김영래, 조병욱

-

Enhancement of Saline Absorbency in CMC/Starch-Based Superabsorbent Polymers by Incorporation of Sodium Bicarbonate

Journal of Korea TAPPI

Journal of Korea TAPPI